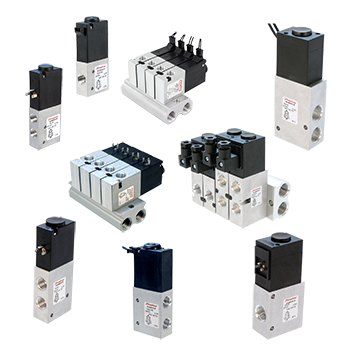

Humphrey – Pneumatic Solenoid Valves

Pneumatic Solenoid Valves: The Humphrey Advantage

Humphrey Products’ pneumatic solenoid valves offer design engineers high-flow efficiency in two-way, three-way, and four-way functions. Our valves accommodate nearly any media, including compressed air, vacuum, and inert gases.

Leading manufacturers prefer the compact, efficient and reliable designs of our pneumatic solenoid valves, and they also benefit from our application experience and the control we maintain over our manufacturing processes.

All Humphrey Products’ pneumatic solenoid valve models are produced with precision machined or molded valve bodies, achieving close tolerance sealing surfaces and the industry’s lowest leak rates. In fact, many of our pneumatic solenoid valve models are deemed “bubble-tight” in application.

Direct-Acting Solenoid Valves

Direct-acting valve types feature compact, fast-switching, Balanced Poppet designs. These multi-purpose valves ensure dependable performance regardless of supply pressure, pressure fluctuations, or valve piping, such as:

- Normally closed or Normally open

- Diverting

- Selecting

- And more

Direct-acting pneumatic solenoid valves offer advantages including:

- Operation under a full pressure range, including low pressure and vacuum

- Simple, reliable construction with fewer parts at a low cost

- Tolerance for poor or unstable media conditions

- Versatility to tailor valves to specific applications

Pilot-Operated Solenoid Valves

These valves use direct-acting solenoid valves as their pilot operators. The pilot operator shifts a larger directional control valve of diaphragm-poppet or piston poppet design.

Pilot-operated pneumatic solenoid valves offer:

- Designs for efficient control of air cylinders and air actuators

- High-flow capacity relative to physical size

- Lower current consumption (amperage) relative to flow capacity

- Various configurations, particularly in four-way applications